Swimming Pool Shocking Caused by Poor Telephone/Power Grounding

Investigators: Doug Dorr, EPRI

Background

This particular case involved a newly constructed swimming pool, installed in compliance to applicable codes and standards for the date of installation in the State of Tennessee, USA. The local electric service provider was called about a shocking complaint around the customer’s swimming pool area, and a subsequent investigation was initiated.

Planning the Investigation

All contact voltage investigations should be initiated with documentation obtained when the initial complaint is received. Once the qualified investigator receives the complaint information, a plan can be developed based upon the investigators initial assessment of the problem. In this particular case, it was determined through the questions asked by the qualified investigators that the complaint involved a “tingling” sensation typical of swimming pools or other “wet use” areas, and a scheduled visit to the site was initiated. Had it been determined that there was a concern about a shock hazard, the site visit would have occurred as quickly as possible instead of a few days later.

Pre-Site Visit Checklist and Equipment List

Before visiting the location, the following determinations were made and subsequent plans put in place:

- A determination was made through a complaint database search that no prior shocking complaints had been logged for that customer or for other customers on the same circuit.

- The one-line circuit diagrams and basic circuit information for the complaint location was identified (primary voltages and configurations, neutral sizes, capacitor bank locations, and so on).

- This customer was identified as the last customer on a single phase lateral, about two circuit miles from the main feeder and about four circuit miles from the substation.

After re-evaluating the initial complaint log and the circuit information, another call was made to the customer prior to the site visit. The additional questions uncovered the following:

- The pool was just completed a few months prior to the complaint call.

- The home was approximately three years old.

- The tingling sensations were felt by the children and the female resident every time that they sat at poolside with their feet in the water, as well as anytime they touched the concrete deck while they were in the pool.

- The male resident could only feel the tingling if he scraped his knuckles and reached into the pool water with his opposite hand or arm placed flat on the wet concrete.

- The electrician had been out to look at the concern and found everything to comply with all applicable electrical codes and correctly wired and bonded.

- The pool installer had been back out to evaluate the situation and found the construction aspects to comply with all applicable codes and the pool correctly installed. The installer suspected the problem to be a “stray voltage” and recommended that the homeowners call their local power company.

- The site visit was scheduled, and the customer indicated that he would request the electrician visit at that time as well. The customer was informed that the investigation would likely involve shutting off breakers for the power service at some point during the investigation.

- Based on this type of complaint (for pool concerns), the power company had an existing checklist of instrumentation and hardware suitable for the type of investigation to be undertaken, along with pre-defined procedures and data forms.

- The power provider did not have any pre-developed literature on contact voltage to communicate the specific issues to the customer, but the customer indicated that he had already learned “more than they ever wanted to know about stray voltage from the internet”!

Site Investigation

Visual Inspection

The investigators started the visual investigation by driving past the serving substation and along the lines leading to the home. This enabled them to determine that everything appeared to be visually normal and to confirm the accuracy of the information detailed in the one-line electrical diagrams. The circuit and service appeared to be normal, and there were no “newer-looking poles” that might indicate a recent accident. New poles can be a sign of recent circuit repairs or pole replacements that were not recorded in the circuit information reviewed prior to the site visit.

After meeting the residents and describing the preliminary plans, the site visual inspection started with the contact complaint location (poolside) and systematically moved upstream to the pump house subpanel, the home’s main service panel, the meter base, and the pole at the service transformer. The site owner gave permission to use a digital camera for documentation purposes.

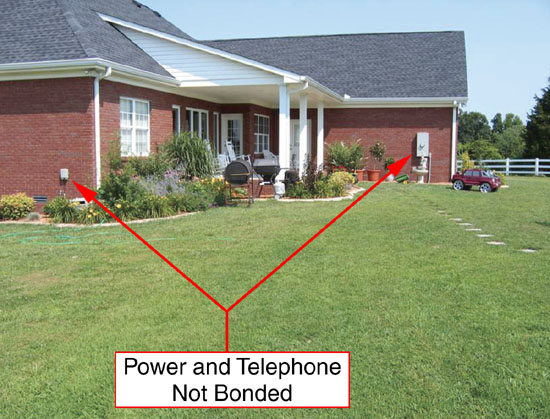

The investigative team noted one abnormal condition related to the NEC requirement for telephone, cable, and power services to be bonded before the services entered the main residence. As shown in Figure 1, the telephone and power services were not bonded at their respective entrances. The team also noted that the pool pump was wired for 120 volts but had a 120/240 dual-winding nameplate.

|

| Figure 1: Telephone and Power Services Not Bonded at Entrance |

Field Measurements

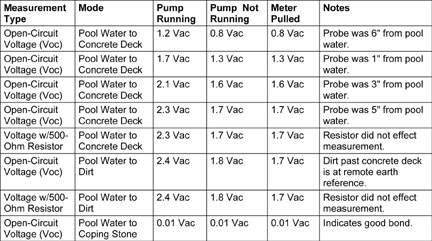

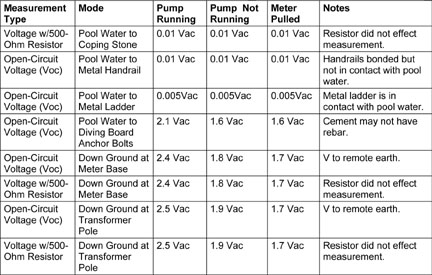

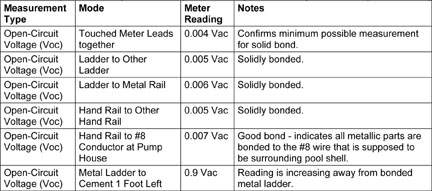

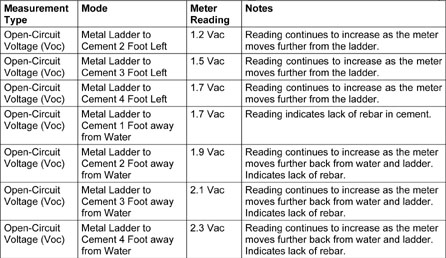

Tables 1, 2, 3, and 4 summarize the measurements obtained during the site investigation. Note that the data in the tables are a summary for the purposes of this case study and does not include all recorded details such as time of day, equipment used, calibration verifications, spectral content, and DC components. Note that in Tables 3 and 4, a meter reading of less than 0.009 indicates a good bond.

|

| Table 1: Measurements at the Site Investigation |

|

| Table 2: Measurements at the Site Investigation (Continued) |

|

| Table 3: Measurements at the Site Investigation (Continued) |

|

| Table 4: Measurements at the Site Investigation (Continued) |

Analysis of Field Measurements

Measurements at the Contact Complaint Point

- Voltage between contact complaint points “with and without” the 500-ohm load resistor did not yield any differences, so the voltage source was able to create a current flow without collapsing. Once the lack of difference was confirmed, this allowed the investigators to reduce the number of measurements required.

- The maximum contact voltage during the investigation was 2.4 Vac, which is enough to create perception concerns. Because 1.7 Vac was present with and without the meter pulled, the indication is that 1.7 Vac was coming from the NEV present on the power distribution system and that the rest was due to operation of loads at the home. It should be noted that the 1.7 Vac measured value will vary over time and season dependent upon circuit loading and grounding resistance. Based on the readings with and without the pump operating, it was clear that rewiring the pump using the 240 V windings (no neutral path) would reduce the contact voltage by as much as 0.5 Vac.

- Based on the voltage readings obtained around the pool, it was clear that all of the metallic parts (excepting the anchor bolts for the slide and the diving board) were properly bonded to the number #8 wire that surrounds the pool shell. The #8 wire could not be visually confirmed because it is covered by the concrete pool deck. However, the meter readings indicated that it is present.

- Because the readings increase as the measurement point moves away from the pool water and away from the bonded metallic parts, this indicates that the concrete does not have rebar. Discussions with the installer confirmed that according to the applicable version of the NEC (2002), fiberglass in the cement was acceptable for the deck construction. Note that the State of Tennessee had not yet approved the change to the 2005 Code (requiring rebar configured as an equipotential plane), even though the pool was constructed in May 2006.

Measurements at Service Panels and Meter Base

All voltages were adequate, and a check for wiring errors was negative. The only exception noted was the lack of bonding of the telephone and electric services before they entered the home. While this did not contribute to the problem with contact voltage, the customer was made aware of the need to have these bonded together to meet code requirements. The NEV measured at the main service panel was essentially the same as at the pool, indicating that the pool water was at the meter-base NEV potential. Pulling the meter base reduced only the NEV portion contributed by approximately 0.6 Vac. The 0.6 Vac was created by the house and pump load, indicating that the greatest source of the NEV (1.7 Vac) was the interconnection between the utility primary neutral and the metallic grounding connections extending out to the swimming pool.

Transformer Pole Down Ground

With the meter base pulled, The NEV measured at the main service panel was essentially the same as at the pool, indicating that the pool water was at the NEV potential of the main transformer pole down ground. This confirmed that the source of the voltage was the interconnection between the utility primary neutral and the metallic grounding connections extending out to the swimming pool. With the meter base pulled, disconnecting the jumper between the primary and secondary neutral removed the NEV at the swimming pool. However, the NEV was still present at the telephone service ground at the home. This indicated that once proper bonding of the services (phone and power grounds) was accomplished, the NEV would get to the pool water regardless of whether or not the jumper was present.

Evaluation of Solutions Options

The analysis and measurements yielded several issues that needed to be addressed. These included:

- Bonding of the telephone and power services at the entrance to the home

- Permanent rewiring of the pool pump for 240-V operation

- Methods to minimize the contact voltage differentials at the pool area

The first two items were addressed within one week, but item three (3) generated some concerns and discussion between the parties involved. The priorities for this case were first to minimize the voltage differentials and second to reduce the voltage present around the pool area. Because the electricians and the installers had done their jobs to the best of their knowledge and ability, within all applicable code requirements, they did not want any further requirement or liability on their part. The utility was concerned that placing a neutral isolator on the pole would warrant liability and future maintenance concerns for them if the problem with the pool deck’s lack of rebar were not addressed concurrently. They did not want a band-aid solution to cover up the real (bonding) problem.

Ultimately, the local electrical inspector and some of the consultants involved agreed that a 4/0 copper ground ring installed about a foot down in the earth and surrounding the perimeter of the concrete deck would be a useful first mitigation step. This would be a much less expensive option as opposed to risking damage to the pool lining by tearing out the entire concrete deck and re-pouring it. The ring was attached to ten eight-foot ground rods driven into the earth around the perimeter to increase the surface area of metal-to-earth contact. This also reduced the overall resistance to earth. The ring was then connected to the #8 ground conductor at the pump house that attaches to the #8 ring around the pool shell. The net effect is that the outer ring, the metal parts, and the pool water should all be at the primary neutral potential, while the concrete deck would be at the earth surface potential developed within the rings. Testing after the ring was installed indicated that the voltage potentials never exceeded 0.5 Vac. It is unclear how much impact this will have over time, but follow-on monitoring with voltage loggers is planned.