Swimming Pool Stray and Contact Voltage Research Outcomes

Electric Power Research Institute – June 2019

DISCLAIMER OF WARRANTIES AND LIMITATION OF LIABILITIES

THIS DOCUMENT WAS PREPARED BY THE ORGANIZATION(S) NAMED BELOW AS AN ACCOUNT OF WORK SPONSORED OR COSPONSORED BY THE ELECTRIC POWER RESEARCH INSTITUTE, INC. (EPRI). NEITHER EPRI, ANY MEMBER OF EPRI, ANY COSPONSOR, THE ORGANIZATION(S) BELOW, NOR ANY PERSON ACTING ON BEHALF OF ANY OF THEM: (A) MAKES ANY WARRANTY OR REPRESENTATION WHATSOEVER, EXPRESS OR IMPLIED, (I) WITH RESPECT TO THE USE OF ANY INFORMATION, APPARATUS, METHOD, PROCESS, OR SIMILAR ITEM DISCLOSED IN THIS DOCUMENT, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, OR (II) THAT SUCH USE DOES NOT INFRINGE ON OR INTERFERE WITH PRIVATELY OWNED RIGHTS, INCLUDING ANY PARTY'S INTELLECTUAL PROPERTY, OR (III) THAT THIS DOCUMENT IS SUITABLE TO ANY PARTICULAR USER'S CIRCUMSTANCE; OR (B) ASSUMES RESPONSIBILITY FOR ANY DAMAGES OR OTHER LIABILITY WHATSOEVER (INCLUDING ANY CONSEQUENTIAL DAMAGES, EVEN IF EPRI OR ANY EPRI REPRESENTATIVE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES) RESULTING FROM YOUR SELECTION OR USE OF THIS DOCUMENT OR ANY INFORMATION, APPARATUS, METHOD, PROCESS, OR SIMILAR ITEM DISCLOSED IN THIS DOCUMENT. REFERENCE HEREIN TO ANY SPECIFIC COMMERCIAL PRODUCT, PROCESS, OR SERVICE BY ITS TRADE NAME, TRADEMARK, MANUFACTURER, OR OTHERWISE, DOES NOT NECESSARILY CONSTITUTE OR IMPLY ITS ENDORSEMENT, RECOMMENDATION, OR FAVORING BY EPRI.

THE ELECTRIC POWER RESEARCH INSTITUTE (EPRI) PREPARED THIS REPORT

Overview

2010 to 2018 testing by EPRI has determined and verified that nuisance tingling sensations for swimming pool users are precursors to a swimming pool that could become an unsafe shock hazard during 120Vac household line faults. To understand this phenomenon from a scientific basis, EPRI has tested two different types of in-ground pool shell designs to include a rebar reinforced conductive shell and a vinyl lined non-conductive shell. Both shell types were evaluated under three different conditions to understand how much voltage can be present between the water and the pool decking during the uncleared electrical fault conditions. The first test condition had all of the pool equipment and conductive parts bonded together but included no equipotential bonding means between the pool water and the deck surface. The second test condition had a single copper ring installed as specified in the National Electric Code NEC Article 680. The third test condition had the NEC Article 680 specifice equipotential grid in the decking around the perimeter of the pool. The primary objectives of the testing were to understand:

- How and why electrical fault voltage can get to the pool water

- Why equipotential bonding of the water, the pool decking and the other bonded parts is so challenging

- Which pool types are at the greatest risk of becoming electrically unsafe

The results provide for an industry that is better informed and better able to develop recommendations to promote effective electrical safety around swimming pool environments. This knowledge is beneficial for pool builders, electrical inspectors, pool shock incident investigators and for pool owners.

Safe versus Unsafe Criteria

Because humans and animals have a range of sensitivities to AC voltage, for the purposes of this document we will define (safe and unsafe) by considering a swimmer immersed in the pool water up to waist level (with both) arms reaching out and in contact with the pool deck. If the water and the deck are at the same voltage potential, no current will flow through the swimmers body. If the water and the deck are at different voltage potentials, currents will flow from the water into the swimmers torso up through the chest area and then through the arms and forearms and into the deck. In this scenario, the greater the voltage difference, the greater the amount of current flow through the chest cavity and heart. To understand how much current is dangerous, the consensus from industry publications such as the IEEE yellow book, Underwriters Laboratories, EPRI and IEEE 1695, consider 5 milliamps (mA) as a perceptible, but safe let-go threshold, 10mA as muscle contraction lock up threshold where injury or drowning could occur, 35mA as a minimum fibrillation threshold of concern for children and 70mA as a minimum fibrillation threshold of concern for adults.

Summary Findings

The remainder of this document will provide evidence necessary to support these conclusions, but for the purposes of summary, the key findings applicable to all in-ground pool types were:

- Uncleared electrical faults from 120/240 Vac residential service, 208Y/120 Vac or 240/120 Vac or 480Y/277 Vac commercial services as well as any higher voltage sources can all create unsafe voltage differences between the water, and all inadequately bonded conductive surfaces in the pool area.

- All pool types tested exhibited a voltage difference between the water and the pool deck during fault conditions, therefore equipotential bonding between the water and the pool deck is necessary regardless of the pool construction type.

- The NEC Article 680 “alternate means” of allowing a single bare copper wire in or beneath the pool deck does not adequately bond the (deck or the earth) to the water or the other conductive parts and therefore no equipotential surface exists, and no safe zone is achievable on the deck during electrical faults.

- The unsafe voltages during these uncleared ground faults cannot be remediated with ground fault circuit interrupters or GFCIs. The GFCI only protects for load faults downstream on just the GFCI circuit.

- All National Electric Code - NEC Article 680 vintages that specify construction with the three-foot horizontal grid of either rebar or copper and requiring all conductive elements to be bonded together promote an electrically safe zone on the deck surface.

- With a properly installed and bonded equipotential grid, the deck and the water and all conductive parts will elevate together during faults and will drop together during normal conditions. The grid should extend at least 3 feet out from the inner pool wall and should be constructed of 1 foot by 1 foot squares.

How and Why Do Faults and Corresponding Voltages Get Coupled to the Pool Area?

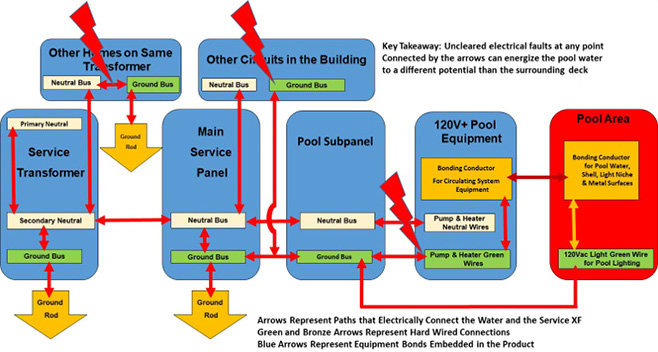

This particular topic can be best understood with a visual as shown in the following two Figures:

Figure 1. Simplified connectivity paths between pool water and the service transformer

Figure 2. Three example locations where an electrical fault will result in energized pool water

Referring to the Figure 1, it is visually apparent that every block is connected to the others by the different colored arrows. Electrically this means that each block has been either (intentionally or unintentionally) bonded or interconnected. This includes the neutral system, the safety grounding system, all of the pool equipment, all metal parts in the pool area, and the water as well as its circulating system. If this seems hard to believe, confirm it by taking an electric resistance or ohm meter reading between a neutral receptacle in a household bedroom or bathroom and connect the other lead to one of the bonded metal parts at the home’s swimming pool. The meter should measure less than one ohm of impedance (resistance) – which is an indication of a continuous connection between them. This effectively means a fault condition anywhere in the home, at a neighbor’s home or on the utility’s neutral side, can each generate elevated voltage levels on the neutral system and subsequently on bonded pool water as visually depicted in Figure 2 and consider that even with GFI protection for the pump, faults that don’t create a phase to neutral imbalance for the GFI protected loads will not be removed from the water area.

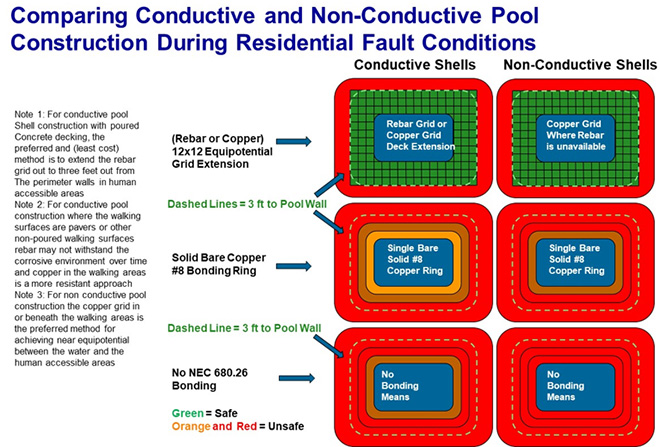

To broadly summarize the issue, all the conductive parts around the pool water must be suitably bonded together. This effectively eliminates the possibility of touch potentials between the metal parts and the pool water, however, bonding of the electrical equipment such as underwater lights, and the water circulating system ends up inadvertently inviting fault voltages and (neutral voltage drop from load currents) directly to the pool water. Since we cannot (effectively) bond the conductive parts to the dirt or earth around the pool, we end up with a voltage difference and shock hazard (during uncleared electrical faults) unless we are standing on some type of equipotential surface. Regarding this concept of insuring the water, the metal parts and the deck areas are at the same voltage potential at all times, the best way to achieve that equipotential surface for a rebar shell construction is to extend that rebar in a horizontal grid configuration (at least three feet outward and encapsulated in the poured concrete decking). When the rebar cannot be extended or encapsulated in the decking material (for example with pavers) or when the pool shell is vinyl or fiberglass lined, a bonded copper grid extending three or more feet from the pool wall is a suitable alternative.

Why is it so Difficult to Bond the Pool Deck?

Simply put, dirt and soil are not bondable because they are not solid materials. Further concrete and pavers are not bondable in the way metal conductive parts are. In fact, about the best we can practically achieve is a connection that is between 1/100th and 1/1000th as good as the bonding we get between metal parts. This is why the rods and grids we use for earthing the power system are called grounding rods and grounding mats as opposed to being called bonding rods or bonding mats. Typical rod and grid resistances between the metal and the earth range from an average value of about 100 ohms to a best case for a really well grounded substation copper grid at about five ohms. To be clear, (we can earth or ground) our electrical systems and get good static charge dissipation, but we can’t effectively bond the system to the earth and eliminate voltage gradients.

What’s the solution: The simple solution is to replicate what is done at power substations. Whereby a (zone of protection) is created on the earth surface where personnel will be walking around and touching equipment. This is done with a conductive metal grid in the earth beneath all areas where humans require safe step and touch potentials. The implementation requires bonding of the metal grid to the other conductive elements and create a (zone of protection) on the surfaces above the metal grid. As a side note, EPRI tests have shown that the deeper the grid is buried beneath the surface, the less effective it becomes in terms of creating an equipotential surface. Therefore, when it is possible, encasing the metallic grid in the decking materials is desirable for both performance and for corrosion longevity.

Which Pool Types Are at the Greatest Risk of Becoming Electrically Unsafe?

To be very clear, any in-ground swimming pool – when properly constructed with an equipotential deck surface and properly bonded parts will be an electrically safe pool for many-many years. Similarly, every in-ground pool type (including conductive and non-conductive shell variations) has the potential for a shock or electrocution concern if any 120 Vac or higher voltage pumps, heaters or underwater luminaires are used.

From a shock risk standpoint there are no fact based scientific ways to quantify exact numbers but there are several considerations that help define the population of at risk pools at risk and the pools at the greatest risk.

Risk Factor One: Every pool with underwater lighting, water circulation or electric heating are at risk of having the water become electrically energized during electrical fault conditions. Since we cannot avoid energizing the water, the best we can do is make sure the water is kept at the same electrical potential as any of the ladders, handrails and deck areas that a human can simultaneously contact. Electrical faults at residential and commercial sites with pools may occur many times over the lifecycle of a swimming pool as do faults on the power system. Some percentage of these faults go uncleared for hours, days, or even years, until someone identifies and remediates the defect. To cite a few examples where data has been documented, The City of Toronto had some shock incidents in 2009 that warranted an immediate inspection of their power distribution system. The inspections uncovered about 1600 shock hazards of which more than 250 were uncleared faults with some portion of the full line voltage. Additional studies show that approximately half of the full line voltage incidents are actually on the customer side of the meter [1]. Additionally, the author of this document can attest to an uncleared fault on his own well pump that went undetected for over two years, until the underground cable finally burned open.

Risk Factor Two: Every pool that has experienced a past shock complaint. These pools are at the greatest risk since the shock complaint is a red flag that the equipotential bonding has been compromised and needs attention. EPRI’s best estimates based on anecdotal discussions with dozens of shock complaint investigators in North America is that the range of shock complaint investigations varies between 500 and 1000 annually across North America.

Risk Factor Three: Pool Construction Type and Code Vintage: With regard to conductive vs non-conductive in ground pools, early research done by EPRI was focused on vinyl and fiberglass lined pools because those were the predominant pools where shock complaints were being investigated, but recent testing has found that it doesn’t matter which pool type – and that all in-ground pool types not containing bonded rebar or copper mesh in the decking can become electrically unsafe during fault conditions. Further, review various vintages of the NEC Articles for Pool equipotential bonding, it is not likely that a bonding ring or a grid will be present in the decking for the majority of pools built before 2005 and only the pools adhering to the three-year cycle prior to 2008 code adoption have the electrically safe grid materials in the decking. The full results of the recent EPRI testing can be found in the Appendix of this document and a high level summary of the results is contained in the (Section 6.0 Detailed test results).

Shock Scenarios of Concern

With a better understanding of Figure 1, and of how (interconnectivity and bonding) actually couple voltages to the pool area, we can describe and envision many scenarios where the pool water gets energized. Unfortunately, the multiple scenarios mean the diagnosis after a fatality or an injury is more challenging.

Common scenario one – conductive shell and underwater lighting: One of the more common scenarios is when the underwater light retaining ring energizes the water. The underwater light ring and the wet niche are electrically connected and electrically bonded to both the bonding conductors and to the safety green wire. The green wire is then electrically continuous all the way back to the main service panel. For older conductive shell pools, we see complaints where swimmers feel tingling in their bodies while fully immersed in the water near the underwater light. For an uncleared fault, a swimmer could be immobilized and drown if they are in the water near the light ring - where the voltage gradients are the largest. This is exactly the same phenomenon that occurs at marinas when a houseboat has an uncleared electrical fault and swimmers near the houseboat lose muscle control and drown. Even with GFI protection on the light circuit, if the fault is not at the light itself, the GFI affords no protection for the ground faults using the green wire as the pathway to the pool water.

Common scenario two – conductive shell and underwater lighting: As a variation of scenario one, when the light ring is energized via the bonded safety green wire and an inadequately bonded metal ladder or handrail is in close proximity the swimmer may become the conduction path for fault current when they are in the water and they touch the inadequately bonded conductive metal element.

Common scenario three – non-conductive shell and underwater lighting: For a non-conductive pool shell the water will hold the full fault voltage potential and if the deck does not contain an adequately bonded mesh, swimmers sitting on the deck with their legs in the water, or persons in the water with their arms on the deck can be fatally shocked or seriously injured. Since the insulated pool liner retains most of the voltage, the swimmer becomes the contact bridge between the water and an inadequately bonded deck.

Common scenario four – faulted water circulation equipment: For either conductive or non-conductive shell pools if the ground fault circuit protector either fails closed or is not present or has been bypassed because of a nuisance tripping issue. Or if the safety green wire is either missing or otherwise does not push enough fault current to trip a protective device, the pool area, or the neighbors pool area will see the fault voltages and currents at the pool water. In general, any of the first three shock scenarios can occur under these field documented scenarios – and the results become more severe if the pool is a saltwater type.

Shock Scenario Summary: All of the described shock scenarios have been documented by EPRI with detailed investigative case studies and the simple conclusion is that while there is never a guarantee that swimmers would not drown or be injured, it is clear that a properly installed and bonded pool and equipotential surface around the pool water will convert these described scenarios from potentially fatal to a scenario where the current and voltage levels are an order of magnitude lower than what they would be with an inadequately bonded system or with a single bare copper ring. Some of these scenarios and the fault conditions are replicated in the next section to contrast the installation scenarios.

Detailed Test Results

Between September 2010 and July 2018 EPRI has conducted a plethora of tests at in ground swimming pool to understand shock and perception concerns with greater technical basis.

The tests conducted provide results for three scenarios as follows:

- Baseline Results – Before any equipotential bonding means have been installed

- Single #8 Solid Bare Copper Ring Results – Where the ring is installed per NEC Article 680.26 specifications.

- Equipotential Grid (#8 Solid Bare Copper) – Where grid is constructed and installed per NEC Article 680.26 specifications.

Key Findings:

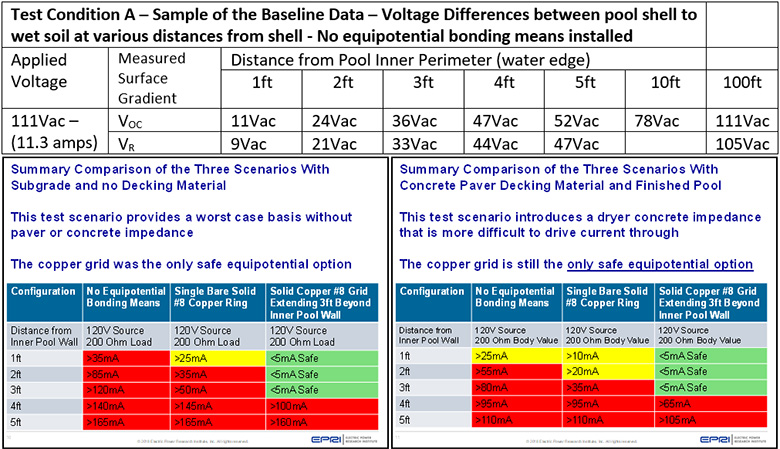

- The overall results of these EPRI tests show that electrical faults from customer side service voltages (120/240) produced unsafe levels of current through humans. The unsafe conditions include scenarios when they are standing on a wet pool area deck and/or when they are simultaneously contacting the decking and water.

- Installing the NEC compliant Solid Bare Copper ring did not reduce the voltage gradient or the currents through the human body to safe levels. The single ring is unsafe during customer faults and within the three-foot perimeter around the pool shell, we measured between 35 and 50 milliamps (mA) of current through the load resistors.

- Installing a Copper Equipotential Grid per the Article 680.26 specifications does reduce the voltage gradient and reduces the corresponding body currents to safe levels. The copper equipotential grid provides a safe equipotential surface during customer faults as we measured less than 5mA of current through the load resistors everywhere within the 3-foot perimeter of interest.

Test Detail: The following figure color codes the test results for the conductive and non-conductive pool shell types and the different equipotential bonding means. The interpretation of the results is based on current levels measure through a load resistor. This enables better definition of safe vs unsafe vs lethal conditions. The results are as follows.

- Areas colored green indicated a safe equipotential condition under all test conditions and at all voltage levels tested. This means the current levels measured through the load resistors remained below ten milliamps

- Areas colored red indicate shock levels that are unsafe. Meaning they would could cause muscle lock-up or heart fibrillation for swimmers (when they are in the water and simultaneously contacting the red deck areas). As a point of reference, with 120Vac faults, the measured currents between the water and the deck were ranging from 35 to 50mA in the red areas (with the bonding ring and were as high as 160mA without the bonding ring

- Areas colored orange or dark orange indicate shock levels that are unsafe but more likely to cause injury as opposed to complete heart fibrillation. These measurements during 120 Vac faults ranged from 10-35 mA.

- The greenish yellow dashed lines indicate the pool deck perimeter zone area at three feet from the inner pool shell. This is the zone of interest where it is desirable to always keep the current levels within the green color or less than 10mA.

- The simple conclusion is the equipotential grid is the only identified safe option under residential 120Vac fault conditions

Figure 3. Summary of EPRI Test Data from 2010 to 2018 Comparing Deck Equipotential Options.

Appendix A

This appendix describes the test setups and summarizes the measurement results from the compendium of In-Ground Pool testing conducted by EPRI. The test procedure was vetted with a team of subject matter experts that regularly conduct test and measurement assessments at in-ground swimming pools. Many of the tests one would normally do in a stray/contact voltage investigation (such as determining a source and verifying the voltage is real and not a static reading) were not necessary here - as we are dealing with known sources and known electrical configurations at test structures. Thus the following assumptions will be verified and then used for the data collected for the test record:

Wet vs Dry Conditions - It is always assumed that wet conditions create greater current flows through a human or an animal than dry conditions. Therefore, for the test record, we first verified the assumption by doing the testing with both wet and dry conditions. The key takeaway: as expected the wet conditions were the worst case.

Load Resistors and Human Body Current Equivalents – For comprehensive testing we evaluated the effects of different values of load resistors in the circuit to understand how they impact measured voltages. The load resistors are useful to determine currents through the body and convert the voltage readings to the more important criteria of body currents through the heart and chest path as well as through the muscle areas. The key takeaway: a 200 ohm load resistor is appropriate for representing a human submerged in a salt water pool with just the arms reaching out onto the decking and a 500 ohm load resistor is appropriate for other conditions such as a human lying on the wet deck with their calves and feet in the water.

Voltage Levels – to verify the assumption that voltages will be linear and consistent, all tests were done with a minimum of three voltage levels. The results were indeed linear - meaning the data can confidently be converted or extrapolated to any other higher or lower fault voltage levels of interest.

Measurement Plates – We did find variations in the voltage levels depending on the size of the deck measurement plate and whether or not a saline solution was used to wet the plate. We additionally found that wetting the plate with the saline solution there was insignificant difference between a 24 square inch and a 48 square inch plate. IEEE 1695 -2016 recommends wetting the plate with salt water as the results become more consistent and repeatable that way. The key takeaway is that a minimum plate size of 48 square inches should be used as that is similar to the surface area of a human’s hands and forearms.

Water Chemistry – The testing clearly shows that salt water pools are more conductive than other chemical compositions. This reduces voltage gradients when the contact concerns are water currents but increases the contact concerns for water to deck and water to handrail concerns. The EPRI tests did not include salt in the pool water but for better measurement consistencies when replicating the tests, it is useful to wet the deck plates with a salt water solution.

Overview

The objective of the testing was to compare the different equipotential bonding options described in NEC article 680.26 and to evaluate how each one performs, relative to one another as well as compared to the case where no equipotential surface is present. These three conditions evaluated include:

- Configuration with just subgrade material and no equipotential ring or grid to get the baseline values.

- Configuration where an NEC 680.26 - 2017 alternate means equipotential bonding ring is used

- Configuration where an NEC 680.26 -2005 alternate means equipotential bonding grid is used

For each configuration a voltage is applied to the equipotential bonding system. This applied voltage is representative of an uncleared power system fault (meaning the breaker at the facility service or subpanel did not open or the GFI did not operate). Once the bonding infrastructure is energized a measurement is recorded to document the difference in voltage between the perimeter bonding infrastructure and the pool decking area. If the equipotential bonding beneath the pool deck is adequate, then the voltage measured between the subgrade, the deck surface, any of the other bonded elements should be less than one tenth of a volt ac, regardless of the applied voltage level. Depending on the meter being used the noise floor may be two or three tenths of a volt ac, so it is important to touch the measurement leads together and use the meter’s noise floor as the baseline and not blindly apply the one tenth volt as the pass fail criteria.

To confirm that equipotential performance is adequate regardless of applied voltage, the tests also consider three different voltage levels applied to the bonding infrastructure. Finally, to verify that the equipotential is maintained throughout the deck areas, the measurements taken are inclusive of (the deck area at different distances) from the pool perimeter (inner wall).

The basic measurement circuit is shown in Figure 4. However, one may want to assess and understand any impacts the water chemistry or the decking materials have on the optimal performance of the bonding network. To understand these variables and their potential to impact the measurements, the tests can be done before the pool is filled with water and repeated again, after the pool is filled with water. Further it is useful to repeat the tests before the surface decking material is laid and test again after the decking is laid. This should provide the optimal equipotential performance results for all test conditions of interest and will promote repeatability if others desire to replicate these results.

Figure 4. Basic Test and Measurement Configuration for the Conductive Pool Construction..

Supporting Background:

To reduce voltage gradients in and around swimming pools, the National Electric Code Article 680.26 requires equipotential bonding for all conductive parts as well as for the deck areas immediately surrounding the pool perimeter. The intent of the equipotential bonding is not to eliminate the voltage gradients – but rather to cause everything within the pool and the surrounding perimeter and decking to elevate together (at or near) the same voltage levels.

A Distinction Between the Terms Grounded and Bonded – Since the pool is in contact with the earth and the all of the bonding conductors and surfaces are all in contact with the earth, the system is naturally earthed or grounded – however, it is important to recognize that grounding only helps to keep static voltages from building up between conductive parts but the grounding does not provide any type of equipotential bonding. In fact, ships and airplanes provide excellent examples of why the equipotential bonding performance does not rely at all on any grounding means or connections to earth.

Expected Results – Since we are aspiring to evaluate equipotential in these tests, the way to consider successful outcomes is as follows:

- Lower voltage numbers equate to better equipotential performance

- By using a load resistor to represent a human body path we can determine the level of current expected and distinguish between safe and unsafe outcomes for each test configuration.

- By using multiple test voltages and proving the results are linear – anyone skilled in the area will be able to convert the results to any other voltage level and expected body currents may be derived.

In other words, the lower the measured voltage difference between the bonded pool infrastructure and the deck area, the better the equipotential performance. If the equipotential bonding below the pool deck is adequate, then the voltage measured between the subgrade any of the other bonded elements should be less than one tenth of a volt ac, regardless of the applied voltage level.

About the Tests – The testing will be designed for consistency and repeatability such that anyone desiring to replicate the results at other pool structures can do so and should expect extremely similar if not identical outcomes and conclusions – while keeping in mind soil composition, water chemistry, decking type, wetness of the test area, size of the deck measurement plate and bury depth of the bonding elements will all shift the baseline levels up or down slightly – but the shift shouldn’t impact the overall linearity or applicability of the results.

To eliminate the possibility of the (deck surface material) skewing the results one way or the other, one of the test leads shall measure the surface of the subgrade (upon which the final deck materials would be poured or laid. To make this measurement connection, a conductive, metal plate of copper, stainless steel or other steel material (at least 48 square inches in surface area) and at least 24 inches long shall be placed on top of the subgrade. This steel plate shall be referred to as the deck measurement point. The steel plate shall be centered at the test distances meaning at the 24 inch distance the plate will be placed 23 inches away and extend to 25 inches away from the pool wall, with the long distance of the plate parallel to the pool wall. The test will be repeated with three voltage levels. The tests will again be replicated once the final deck surface is installed.

To eliminate the possibility of (water chemistry) skewing the results one way or the other, the second test lead shall connect directly or indirectly through a bonding conductor extension, to one of the #8 solid copper pigtails that are bonded to the rebar and encased in the Gunite shell. To further eliminate any skewing, all testing is to be conducted before (and then again after) the pool is filled with water. This second test lead shall be referred to as the (bonded parts measurement point).

Measurement Protocol – Referring back to figure one as a reference, the following test procedure shall be used:

- Connect the voltage source hot lead to the bonding infrastructure of the pool and connect the voltage source neutral lead to a remote earth ground rod (driven at least 40 feet away from the pool perimeter).

- Energize the voltage source and apply 120Vac to the bonding infrastructure in the pool.

- Verify with a voltmeter that the applied voltage is present between the remote earth ground rod and various bonded elements in the pool area (rebar or pigtails, bonding ring and any other exposed metal parts).

- Connect the leads to the measurement points as shown in Figure One.

- Record the measured voltages with the deck measurement point lead placed approximately (one foot away) from the pool perimeter and repeat the process at 2,3,4 and 5 feet distance away from the pool perimeter. Record the (open circuit voltage or VOC) measurements with the designation VOC -1ft, VOC -2ft, etc.

- Repeat step five with a 500ohm resistor placed across the meter leads. Record the measurements with the designation V500-1ft, V500-2ft, etc.

- Repeat step five with a 200ohm resistor placed across the meter leads. Record the measurements with the designation V200-1ft, V200-2ft, etc.

- Repeat step five with a 1000 ohm resistor placed across the meter leads. Record the measurements with the designation V1000-1ft, V1000-2ft, etc.

- Repeat steps one to eight with a second voltage – such as half or twice the original test voltage

- Repeat steps one to eight with a third voltage – such as 25% of the original test voltage

This same test procedure is repeated for the following three configurations:

- Baseline: With plain subgrade around the pool and no equipotential bonding ring or grid

- With the NEC Article 680.26 compliant equipotential ring

- With the NEC Article 680.26 compliant supplemental copper equipotential grid

Results: From the Conductive Pool Shell Tests

Figure 5. Summary Tables with Configuration Results and Current Measurements for the Conductive Pool Shell Tests.